Pressure Relief Valves Can Only Be Installed in Parallel

A technician should look for ______ when first inspecting a leaking system system with a hermetically sealed compressor. Pressure relief valves can only be installed.

Relief Valves An Overview Sciencedirect Topics

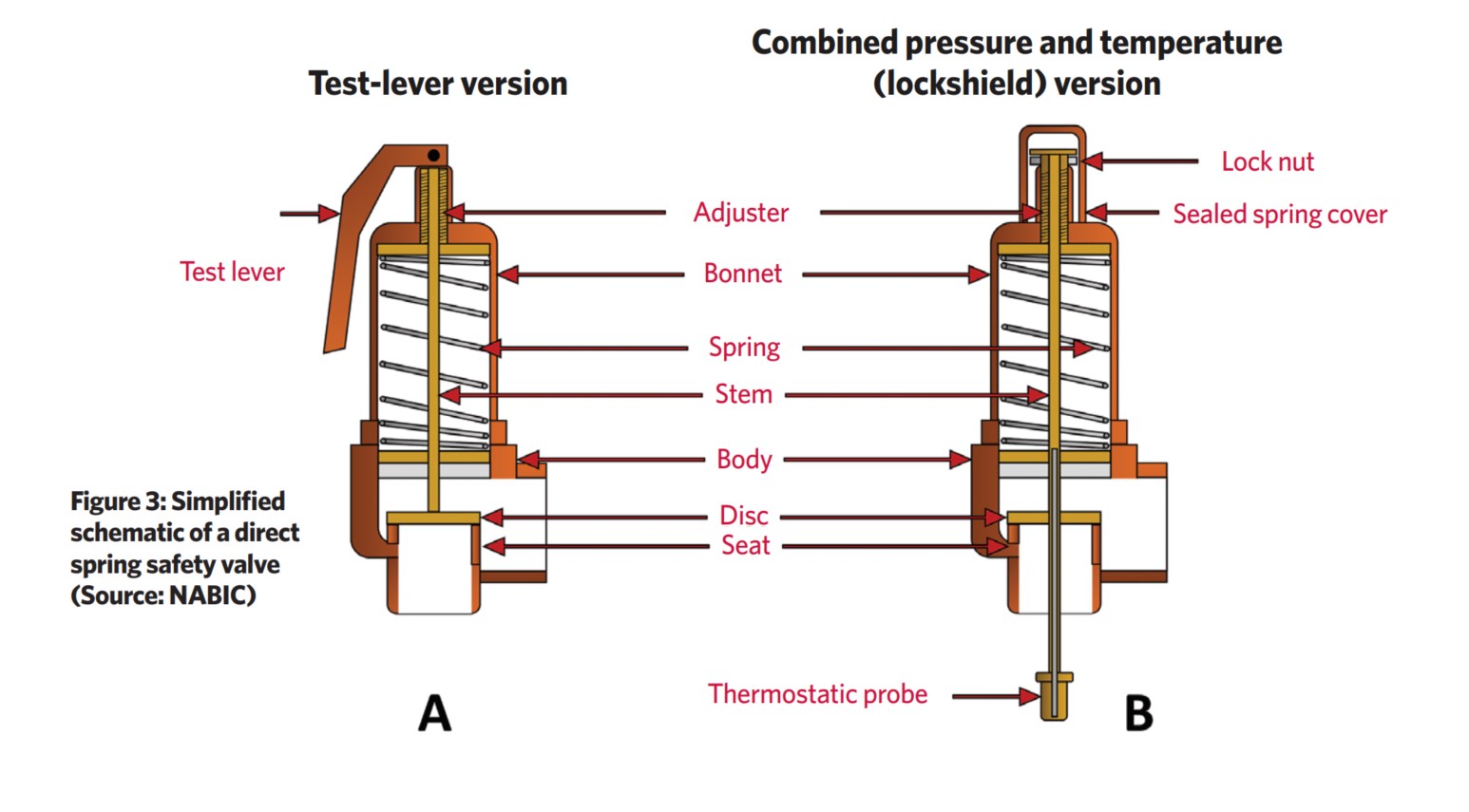

Mount PRVs in a vertical position which means upright and with the spindle vertical.

. - The relieving fluids may impede the proper operation of the pressure relief valve. Pressure Build-up A relief valve has a setpoint at which it begins to open. All of the above.

2nd device cannot be higher than 105 of. The seat tightness operation and set pressure of the valve may be affected. Every refrigerating system must be protected by which of the following.

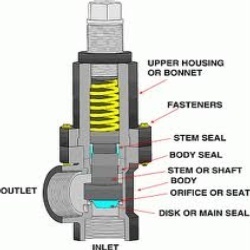

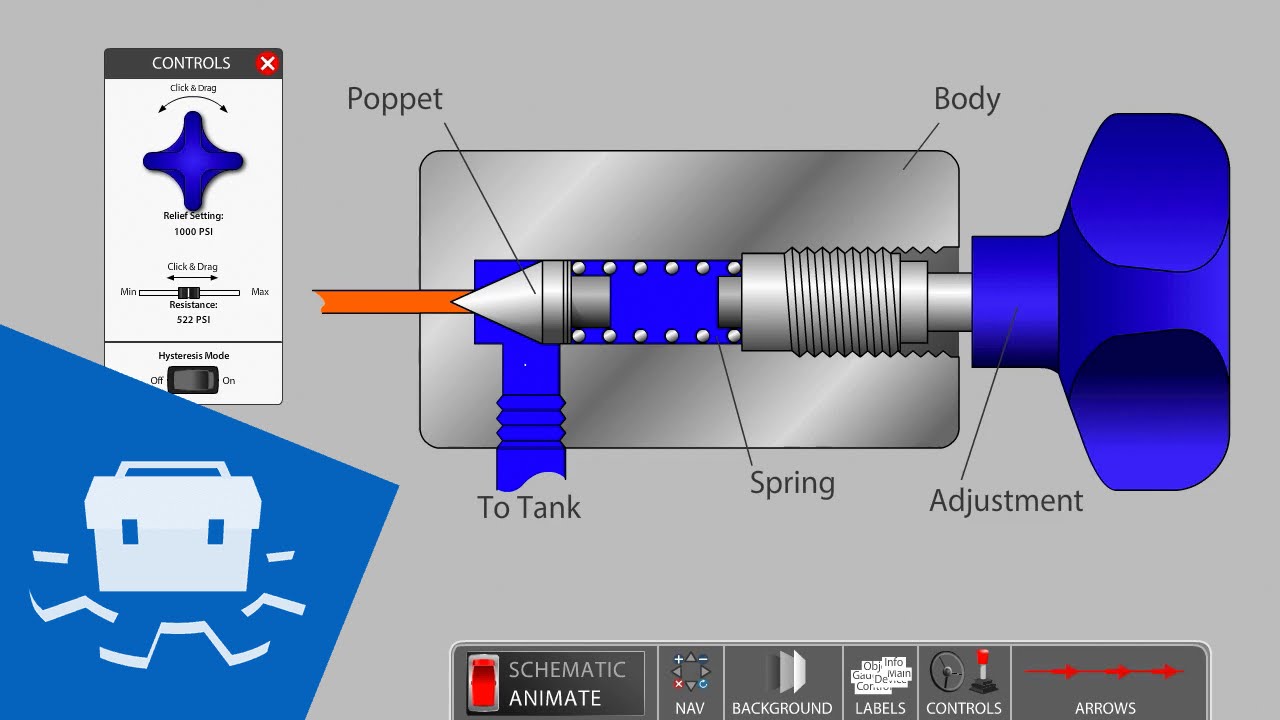

The pressure set value must be higher than the test range but it does not exceed the allowable. There is no reason not to trap liquid refrigerant in the hose since it will avoid venting of refrigerant. Pressure relief valves are essential components in keeping hydraulic and pneumatic systems below a set pressure.

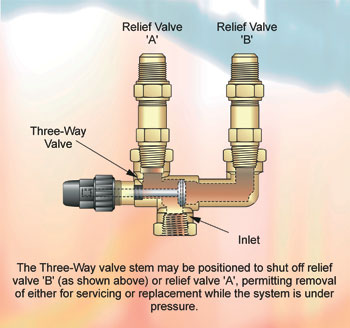

To guarantee that your valves are installed correctly and prevent damage to both the valve and the system. When control valves are installed in parallel they are set up for split range so they dont fight each other. Relief Valves in Parallel Author.

Periodic Maintenance A relief valve installed in a system that. All EBVT-PR ball valves may be installed in any position. The valve seats can freeze.

12242009 1105 PM. A properly located stop valve. This will also increase the lockup pressure and.

Relief valve is opening due to a fast-acting device downstream pneumatic control valve or solenoid valve and. Mount PRVs in a vertical position which means upright and with the spindle vertical. A pressure relief device.

Maintain sustained pressures down- or. 1 1 relief valve set pressure 7barg. A safety valve mounted in a non-vertical orientation may not perform as expected.

Only one need be set at or below MAWP. As demand increases the second valve opens. A valve installed in any position other than vertical might not perform correctly.

A low pressure control. Assume its designed for 600kghr steam flow rate. 2 15 relief valve set pressure 8barg.

Pressure relief valve installation MOUNTING. Especially in the initial stage because the required flow rate is very small it is often below 01 Lmin. A valve installed in any position other than vertical might not perform correctly.

A pressure relief device designed to actuate on. Here is my current problem. For flanged valves be sure to draw the bolts down evenly.

This requires that the set to open pressure of the relief valve be below the burst pressure range of the bursting disc with a. There is no pressure relief valve on the typical hose and the liquid refrigerant trapped in the hose could build up significant pressure and rupture the hose. This is especially crucial for cast iron valves.

Reduce the downstream pressure to a constant level whenever it exceeds a threshold. Not quite sure if I understand your operation. Low loss fittings are required since January 1992.

A refrigerant receiver A. This 1HP HMS pump model 2HM1E2D variable speed constant pressure pump is set to give me 50 PSI at the pump outlet. Please note second valve was added to add extra layer of protection for a higher flow rate in case of rarely possible worst case scenario assuming first one does not lift.

The same should apply to parallel relief. Parallel prv relief valve safety Created Date. In parallel Decks in I9 Class 4.

Pressure Relief Valves - How They Work. This 5 story 5 family building with 5 bathrooms 5 kitchen sinks and dishwashers needed to have a Gould Aquaboost II installed 7 years ago because the City water pressure was only 32 psi. Installation of the 332-inch orifice will reduce the sensitivity capacity and accuracy of control of the Series 2000 valve.

A low pressure control. When using rupture discs and relief valves in parallel a suitable margin of set pressure needs to be introduced to avoid premature failure of the rupture disc. Improperly installed valves can both cause leakage and pose safety risks.

A pressure relief device. 25 Pressure relief valves can only be installed. Stainless steel stop plate ensures fully open to fully closed with a 14 turn.

Using multiple speed control valves in parallel or bypass throttle valve can take in to consideration. A relief valve may still be installed in parallel to protect against other relieving scenarios. -pressure relief device -gauge manifold -service king valve -all of the above.

The A side of the ball valve should always be on the same side as the coil. Depending on the installation they can either. Pressure control valve a regulator.

Pressure Relief A Pressure Relief SUCTION LIQUID Evaporator Coil Note. Please note that it is usually acceptable to have 5 of maldistribution on equipment in parallel and with 3 set pressure loss this should not be a big difference. One valve opens first and handles part of the demand.

If you are using a 13 - 23 valve arrangement in parallel the reason is to keep the valve seats from wire drawing when the capacity requirement closes the valve to near 0. Assume its designed for 300kghr steam. Here are 3 signs of pressure relief valve failure to watch out for.

All ports open. The pressure relief valve in the system is used for safety protection only. For flanged valves be sure to draw the bolts down evenly.

A properly located stop valve. All EBVT-PR ball valves use C19400 K65. Desired pressure drop Δ P across the Series 2000 valve is 50 psig or more.

It is my understanding that valves can be designed with the same set pressure as long as the above points are reviewed even if inlet lines are not symmetrical. This is known as pressure build-up over setpoint or simply build-up. For the valve to fully open and pass the maximum flow pressure must build up to some level above the setpoint of the relief valve.

That said pressure relief valves can and do fail and its important to be able to recognize the signs in order to quickly solve the problem and keep your facility safe. James R Lawrence Sr. A ______ must protect all air conditioning and refrigeration systems.

The theory requires the 13 valve to open fully and then have the 23 valve open for additional capacity. A pressure relief device. Pressure relief valve installation Mounting.

This is especially crucial for cast iron valves.

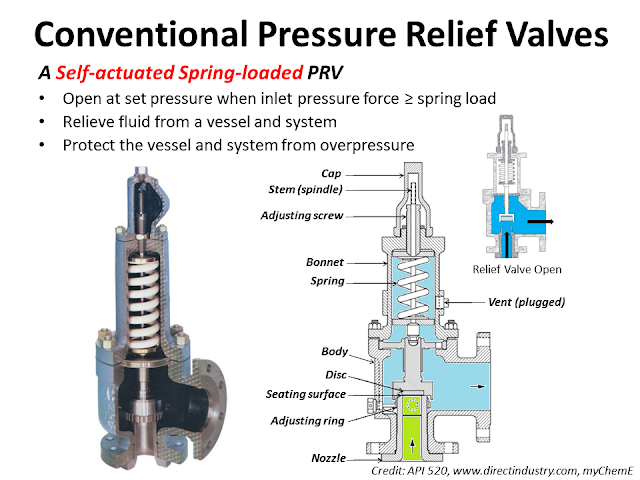

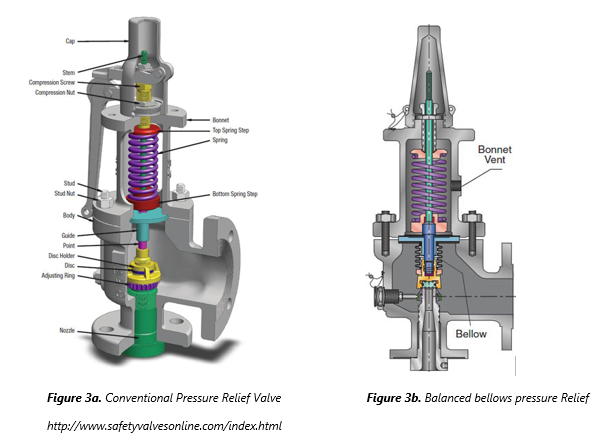

Conventional Pressure Relief Valve Component Intro Amarine

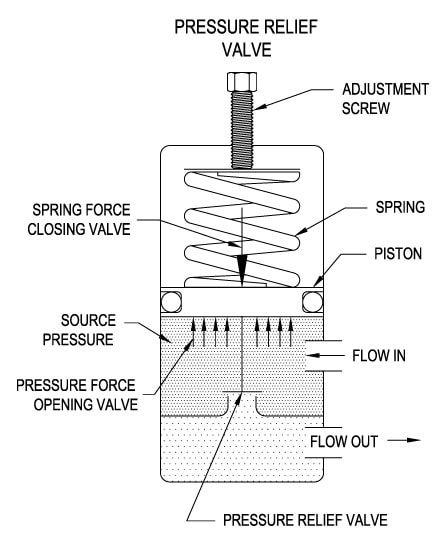

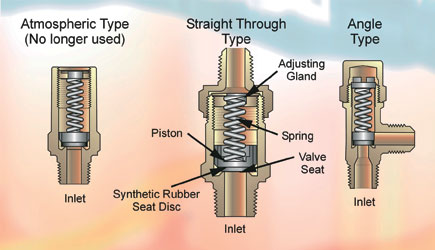

The Basics Of Pressure Relief Valves Beswick Engineering

Masterclass Pressure Relief Safety Devices Part 18

Introduction To Valves Only The Basics Introduction To Block Bleed Valves And Block Bleed Systems Valve Ladder Logic Relief Valve

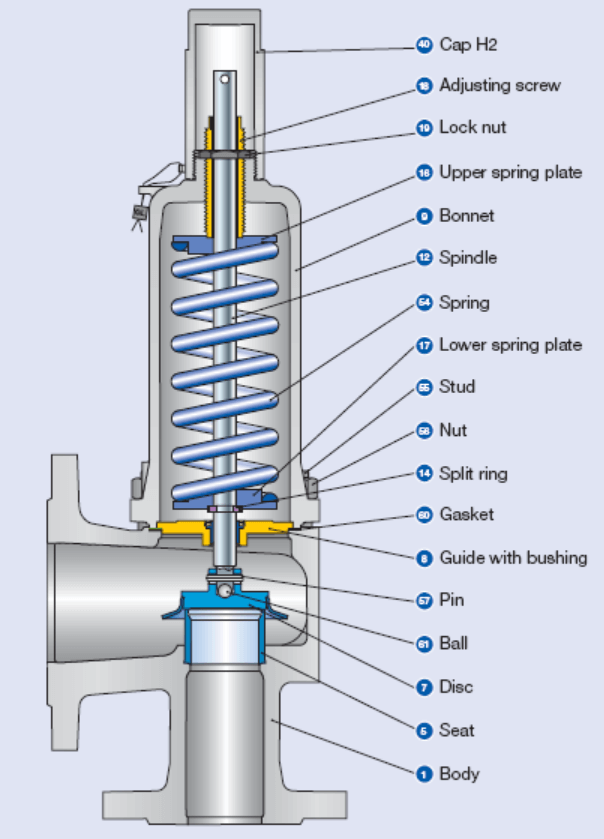

Spring Loaded Psv Model A Spring Loaded Pressure Safety Valve Is A Download Scientific Diagram

Set Pressure An Overview Sciencedirect Topics

Pressure Relief Valve And Pressure Safety Valve Types And Working The Piping Talk

Hydraulic Power Systems Valves Part Three

Module 168 Safety Valves For Building Services Systems Cibse Journal

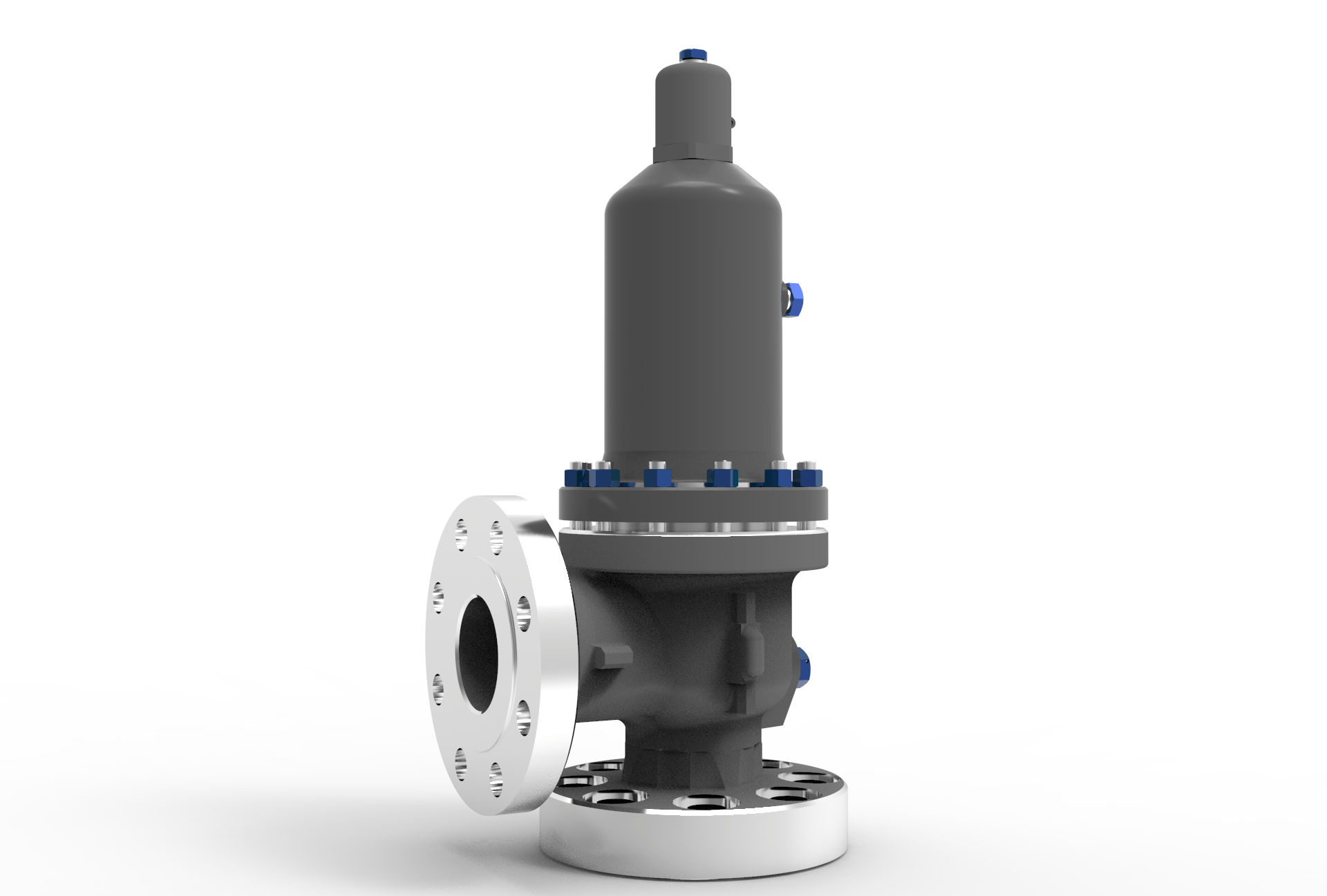

Starflow P Series Pressure Relief Valve Trillium Flow Technologies

What Is A Pressure Relief Valve Instrumentation And Control Engineering

Asme Pressure Relief Valve Testing Validyne Engineering

Direct Acting Relief Valve Youtube

Masterclass Pressure Relief Safety Devices Part 18

El Maquinante Safety Relief Valves

Pressure Relief Valves How They Work Tameson Com

What Is A Pressure Relief Valve Instrumentation And Control Engineering

Comments

Post a Comment